24 Jun

OSHA inspection checklists are the best way to prepare yourself, your company, and your employees for OSHA compliance. The idea is to use these lists to conduct a self-audit and assess your performance against OSHA standards beforehand to avoid surprises during the actual check. In this article, we discuss a wide range of OSHA inspection checklists and the variations between each.

What is OSHA?

To enforce better health and safety standards and practices in the workplace and protect the rights of employees, the US Department of Labour introduced the Occupational Safety and Health Act in 1970 (OSH Act). Thereby, the Occupational Safety and Health Administration (OSHA) took root under this act. OSHA then implemented a set of “standards” for every employer within its jurisdiction to follow and maintain.

Why is an OSHA inspection necessary?

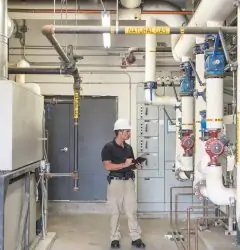

An OSHA inspection is how the Administration ensures that employers stay in line with OSHA standards. Every workplace, be it office, warehouse, shop, factory, or construction worksite must identify the relevant standards, understand them, and then implement them. Additionally, employers must provide the appropriate knowledge building exercises, training, and so on.

Moreover, OSHA may sometimes conduct an inspection either in response to a complaint or as a random check. These inspections are thorough and, should an employer fail, can lead to severe fines or, in extreme cases, cease and desist orders.

What triggers an OSHA inspection?

Several situations can trigger a response from OSHA and force an inspection. The most common trigger is employee complaints. Unsatisfied employees are well within their rights to report the situation to OSHA, thereby prompting an investigation.

On the other hand, OSHA routinely inspects industries that inherently require the use of dangerous chemicals and other hazardous materials such as oil refineries and tanneries. Similarly, industries such as construction and shipbuilding can create situations that present imminent danger which, without the appropriate safety equipment, would be life-threatening.

What happens during an OSHA inspection?

An OSHA inspection usually takes place in three parts. The arrival/opening conference, on-site inspection, and closing conference. The OSHA team can, at any time, arrive unannounced, enter without delay, question employees privately, maintain complete confidentiality, and determine who participates in an inspection.

How can using an OSHA inspection checklist help?

Using an OSHA inspection checklist helps create an organized and coordinated approach to self-assessment. In other words, avoid any surprises during the actual OSHA inspection, which can lead to several ramifications, especially during the Covid-19 pandemic. In this case, all employers must take the utmost care to ensure the safety of their workers and their customers.

Mock OSHA Inspection Checklist

The contents of an OSHA inspection checklist may vary from industry to industry, the format, however, remains the same. The structure usually includes a categorized list of things that require verification with a small box for checkmarks adjacent to the text. According to the OSHA Small Business Handbook, in most cases, an inspection checklist can look like this:

Employer Posting

- Is the required OSHA Job Safety and Heath Protection Poster displayed in a prominent location where all employees are likely to see it?

- Are emergency telephone numbers posted where they can be readily found in case of emergency?

- Where employees may be exposed to toxic substances or harmful physical agents, has appropriate information concerning employee access to medical and exposure records and Material Safety Data Sheets (MSDSs) been posted or otherwise made readily available to affected employees?

- Are signs concerning exit routes, room capacities, floor loading, biohazards, exposures to x-ray, microwave, or other harmful radiation or substances posted where appropriate?

- Is the summary of Work-Related injuries and illnesses (OSHA form 300A) posted during the months of February, March, and April?

Record Keeping

- Are occupational injuries or illnesses, except minor injuries requiring only first aid, recorded as required on the OSHA 300 log?

- Are employee medical records and records of employee exposure to hazardous substances or harmful physical agents up-to-date and in compliance with current OSHA standards?

- Are employee training records kept and accessible for review by employees, as required by OSHA standards?

- Have arrangements been made to retain records for the time required for each specific type of record? (Some records must be maintained for at least 40 years)

- Are operating permits and records up-to-date for items such as elevators, air pressure tanks, liquefied petroleum gas tanks, etc.?

OSHA Inspection Checklist for General Industry

An OSHA inspection checklist for General Industry applies to all sectors regardless. Some of the most commonly cited OSHA violations for General Industry in 2018 included:

- Hazard communication standard;

- Respiratory protection;

- Control of hazardous energy (lockout/Tagout);

- Powered industrial trucks;

- Machinery and Machine Guarding;

- Eye and Face Protection.

Here we discuss some typical General Industry OSHA inspection checklists you should keep in mind.

OSHA First Aid Kit Inspection Checklist

An OSHA first aid kit inspection checklist can include questions like:

- Is the first aid kit fully supplied and easily accessible?

- Has a licensed physician approved the first aid kit?

- Is there an eyewash station or sink available with quick drenching capabilities?

- Have all personnel that must respond to medical emergencies as part of their job responsibilities received the appropriate first aid training?

OSHA Eye Wash Station Inspection Checklist

This OSHA inspection checklist if relatively straightforward. You have to check whether:

- The eyewash station is operational;

- There are any parts broken or damaged;

- The station operates the way it should.

OSHA Fire Protection Inspection Checklist

A fire protection checklist includes all safety elements concerning the prevention of fire, safety protocols in case of a fire and tools and equipment necessary for personal protection. Some for the questions you can answer through your self-inspection checklist include:

- Is a fire alarm system installed? If so, is it certified and tested regularly?

- Are fire doors and shutters clear of obstacles?

- Are portable fire extinguishers available and easily accessible?

- Are the fire extinguishers regularly recharged?

OSHA Vehicle Safety Inspection Checklist

A vehicle safety inspection checklist covers vehicle components that carry dangerous material, control the vehicle, i.e. start and stop as well as general safety measures such as:

- Are cars and other motorized equipment inspected daily or before first use?

- Are vehicle shut off systems and brakes checked before use?

- Is there enough clearance on all sides of the vehicle along the expected route within the facility?

- Do employees that operate vehicles outside the facility adequately licensed?

OSHA Inspection Checklist for Construction

OSHA inspection checklist for construction usually revolves around preventing accidents at height, secure work surfaces, and operating heavy machinery/equipment. Some of the most often cited OSHA standards for construction include:

- Fall protection;

- Fall Protection–Training Requirements;

- Scaffolding, general requirements;

- Ladders.

OSHA Ladder Inspection Checklist

Usually, a ladder inspection checklist covers the structural integrity of the ladder and the knowledge required to use one safely. You can ask questions such as:

- Are all available ladders in good condition?

- Is each step or rung covered by non-slip safety feet and free of grease or oil?

- Are employees aware not to place the ladder on unstable surfaces such as boxes and barrels?

- Are metal ladders regularly inspected for damage?

OSHA Overhead Crane Inspection Checklist

Overhead and gantry cranes take skill to operate and therefore, require proper regulation in use and maintenance. If you use an overhead crane in your workplace, here’s a list of things you should include in your OSHA inspection checklist:

- Is the crane’s rated load visible in a prominent location on either side?

- Are bumpers installed on the bridge or trolley in case of high-speed movement? Are the bumpers in good condition?

- Are there guards in place to protect the hoisting mechanism from any electrical conductors/wiring?

OSHA Mobile Crane Inspection Checklist

A mobile crane, if used correctly, provides a convenient and reliable method of moving objects to and from differing heights or across significant gaps. An OSHA inspection checklist for a mobile crane should include:

- Does a competent and certified technician inspect the hoisting mechanism regularly?

- Are physical barriers available and used appropriately while the crane is in operations?

- Is the crane operated and maintained solely by the designated personnel?

OSHA Scaffold Inspection Checklist

Scaffolding is a temporary structure used to support workers and the handling of materials during the construction, maintenance, or repair of large buildings and other human-made structures. Most commonly, scaffolding related injuries are caused by falling. Your scaffold inspection checklist can include the following items:

- Are all tools and materials kept away from any energized power distribution lines?

- Is the scaffolding at least ten feet away from any energized power distribution lines?

- Are all footings correct for the required load?

- Are there regular checks for any damage to joints, supports, and rigging?

OSHA Fall Protection Inspection Checklist

Fall protection inspection involves removing trip hazards, securing floor openings, and walkways. To that effect, your OSHA fall protection inspection checklist should include things like:

- Are workers exposed to a fall of six feet or more secured adequately to their worksite?

- Do all floor openings have adequate coverings and guards to ensure they do not open accidentally?

- Are walking surfaces sturdy enough o support workers as well as any materials they may carry?

- Is each employee that is working in a hoist area protected by guard rails or personal fall arrest systems?

- Is a safety harness inspection conducted daily before first use?

OSHA Electrical Inspection Checklist

Electrical hazards exist in every workplace. However, none more so than when renovating or repairing old structures. In this case, the power distribution system is often dilapidated and outdated. Therefore, employers must make sure thoroughly inspect all areas where exposed energized wires come into contact with people. Your electrical inspection checklist can include elements such as:

- Are recognized electrical hazards in electrical equipment identified and made apparent?

- Are energized electrical parts guarded against accidental contact?

- Is the correct outlet used for the load it bears?

- Are lamps and other electrical light sources protected against breakage?

OSHA Equipment Inspection Checklist

Any construction or development project requires several different kinds of equipment. According to OSHA’s Small Businesses Handbook, Personal Protective Equipment (PPE), hand tools and equipment, portable (powered) tools and equipment, abrasive wheel equipment, hoist, and auxiliary equipment, and sanitizing equipment and clothing. Therefore, before creating a checklist, you need to identify what kind of stuff you use at the worksite and how to maintain or dispose of them. Your checklist can include questions like:

- Is protective gear for the head, ears, face, and feet worn at all times where there is a risk of trauma from falling objects, flying debris, or electric shock?

- Are employees working on or near large bodies of water wearing certified and approved life jackets or buoyancy device?

- Are all hand tools with exposed metal parts kept clean and free of rust?

- Are all powered tools stored correctly to avoid damage to the equipment while remaining accessible?

OSHA Forklift Inspection Checklist

Forklifts are a significant contributor to worksite accidents and sometimes death. Usually, accidents stem from the operator mishandling the vehicle or failing to understand the rated load capacity. Your forklift inspection checklist should make sure to cover things like:

- Are the forklift operators competent enough to operate the vehicle as advised?

- Is the forklift inspected daily before use for damage, leaks, and general maintenance?

- Is refresher training provided to all relevant employees about forklift safety annually?

- Is there sufficient headroom above a forklift’s maximum operating height?

OSHA Hoist Inspection Checklist

There are many different types of hoists and elevators used around a construction site for both personnel and materials. According to the South Carolina Department of Labour, hoist safety guidelines should include:

- Do appropriate gates, guardrails or fences protect hoistway entrances?

- Are hoistway doors and gates intended for personnel use at least six feet six inches high?

- Are overhead protective coverings in place?

- Is the rated load capacity visible in a prominent location on the elevator or hoist?

- Is a sling inspection carried out before every use?

- Are records maintained for these inspections?

OSHA Facility Inspection Checklist

Every facility, whether it is a warehouse, restaurant, or office, must adhere to OSHA health and safety regulations. In most cases, OSHA General Industry standards will cover most aspects of work-life within any facility. However, depending on the scope of the business, you may need to expand your scope.

OSHA Warehouse Inspection Checklist

In a warehouse, accidents and injuries typically occur as a result of falls, heavy material falling or mishandling machinery. Any warehouse inspection checklist should incorporate many lists we have covered so far, such as forklifts, hoists, cranes, material handling, and more. In terms of general warehouse safety, your listing can ask questions like:

- Are all floors and aisles clear of unused material, clutter, and debris?

- Are the floors and other work surfaces over which personnel may carry heavy loads free of slip and trip hazards such as grease and ropes?

- Have all employees received the appropriate ergonomic training as required by OSHA?

- Is the warehouse ventilation system operating efficiently?

- Are the ventilation systems cleaned regularly?

OSHA Office/Shop Inspection Checklist

As far as shops are concerned, the appropriate OSHA inspection checklist will change depending on the nature of the business. However, here we will discuss typical offices and retail outlets for consumer goods. In this case, your inspection checklist should include questions like:

- Have all flammable or hazardous chemicals been identified and marked?

- Have all employees received training for handling fragile material?

- Is a fire extinguisher available within easy reach of the employees (from Fire Protection standard in General Industry)

- Is the lighting adequate for both daytime and nighttime operations?

- Have all employees received first aid training?

OSHA Restaurant Inspection Checklist

A restaurant has more potential for health safety disasters than you might think. For the most part, everyday operations involve using butane for firing stoves, sharp utensils, flammable drinks, and much more. Your inspection checklist would have to cover fire protection, personal protective equipment, hazard recognition, eye and face protection, use of the hardware, and much more. Your OSHA inspection checklist can include some of the following questions:

- Is there a ventilation system for clearing smoke in case of a fire?

- Are valves and regulators used for fuel tanks regularly checked for damage and leakages?

- Are the moving parts of any machinery guarded against direct contact with the employee?

- Have employees received training as to the correct operating procedures for each machine?

Conclusion

Remember that OSHA’s objective is to protect the civil and human rights of employees in all workplaces. If you keep the same mindset in mind when developing your OSHA inspection checklist, you can pass inspections with ease, or avoid them altogether.

Ecodocs