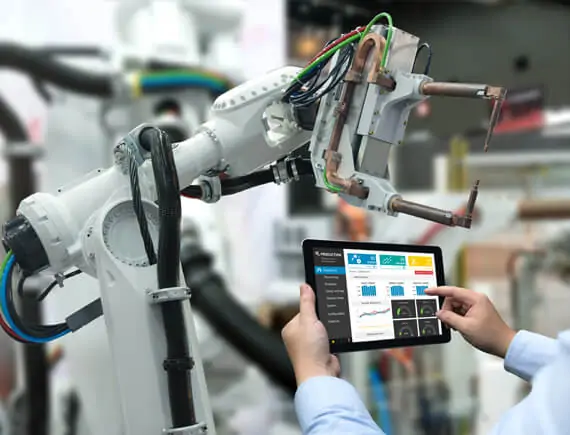

Maximize asset uptime and take maintenance to another level by predicting breakdowns before their occurrence

Managers can predict asset breakdowns, prioritize assets, and plan and schedule cost-efficient maintenance work orders before the need arises by using our predictive maintenance software system.